When I saw the trailer to this movie I was disappointed, trailer introduced just another low quality martial arts movie made in Thailand and absolutely not reflecting back the spirit of the previous flick. But I hoped if there is Michael Jai White involved as a director and a lead star the movie should be done on the level enough to impress the fans. And I was right!

Even if the first scenes made in a low budget sets and remind Undisputed 3, what is not bad at all, but when the story moves to Thailand everything becomes much more promising.

When Van Damme takes his children Kris and Bianca into his movies this doesn’t bring the movie any benefits, but in case with White’s family it works very well. I clearly understand why Gillian and Michael made a Black Hollywood’s newest couple with a focus on health & fitness. Gillian who wanted to become an FBI agent but changed her major to Human Communication and minored in Dramatic Arts, and Michael – ex-teacher and very educated and complete martial artist of our time, made a perfect motivation to hit the gym today and pursue the dream.

But let’s get back to the movie.

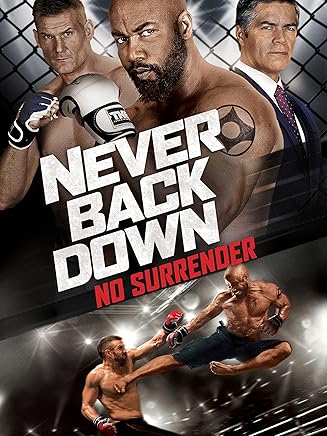

Picking up after the events of Never Back Down 2, former MMA champion Case Walker wants to help his friend Brody James prepare to the fight with a killing machine Braga, but finds himself involved in a dirty business of underground fights in Thailand.

And there starts the most interesting part of the movie where old school meets new school. Michael, whose favourite style is Kyokushin Karate, demonstrates us the purpose of kata and proves that it is not just a dance on the floor with fancy moves but the real deal. Watch it and you will understand.

Moreover he explains to his two students that punching the bag takes you into an illusion that you make a punch, but when you train on Makiwara and if your distance is wrong and technique sucks, you will really feel the pain.

Brody James played by the real UFC champion Josh Barnett who claims a mixed martial arts record of 50-7 and #8 in the official UFC heavyweight rankings. What is interesting at the age of 17 he saw UFC 4 and decided to become a MMA fighter. 6 years later he made his debut at UFC 28 already holding a 9-0 record.

I really liked the character of Cobra O’Conor played by Eoin O’Brien. Yes he is arrogant and provoking but he has his style reminding Conor McGregor.

I wouldn’t say a word about Tony Jaa‘s appearance in this movie, I think guys just had fun, but I was really impressed with outstanding technique of Jeeja Yanin, this girl should get more exposure as she really deserves it. The scene where she is punishing the arrogant fighter played by Brahim Achabbakhe using so recognisable now Muay Thai moves will make you stare at the screen and say “Wow!”. Beautiful choreography! And don’t miss her training sets on the bag!

There is a really strange character of Russian Sambo fighter Boris played by Aaron Brumfield, probably made to show that Russians bring only the bad things from the standpoint of latest world events. Two guys training in the gym and fighting against much better fighters is another weird storyline but let’s leave it to Chris Hauty.

Award-winning actor Esai Morales is really good as a promoter and taking him for this role was a clever decision. His champion Braga played by 6′ 11″ Australian giant Nathan Jones, mostly known by his role in the Fearless movie alongside Jet Li, looks really impressive but not crazy enough to believe he is a brutal monster, especially when it comes to the fight with Casey Walker.

But what gives him some credits that he made Michael Jai White fall on the floor in knockdown what has happened the first time in his movies! In the previous films Michael always played an unstoppable machine but here he takes punches to the face like any one else.

Summarizing everything I must say Michael Jai White uses effective street fighting techniques against sport MMA style and proves that original Kyokushin Karate was developed for a self defence, and a strong spirit, healthy body and clear mind are the main pillars of the real fighter.

Good job Michael, please keep it up!

PS: Rampage Jackson sent a very cool video message to Casey Walker. Guys done a great job promoting their new movie Cops and Robbers coming out this year.